Aero-Box Aerodynamic roof boxes

|

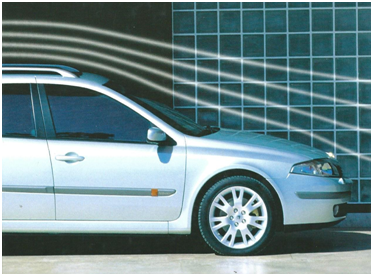

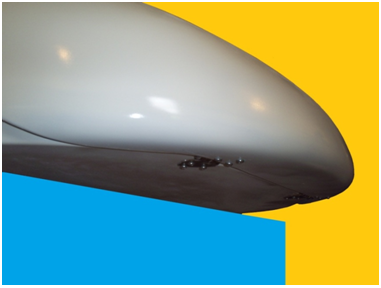

This is what the

airflow round a standard car looks like. Its windshield pushes air

upwards.

|

|

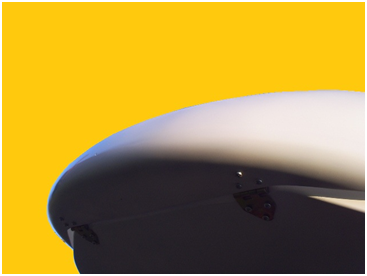

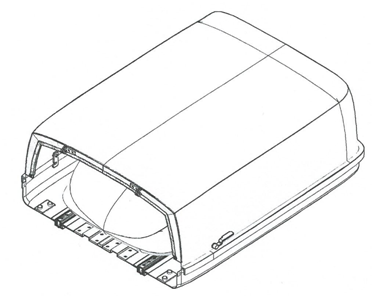

Front view of a standard box |

|

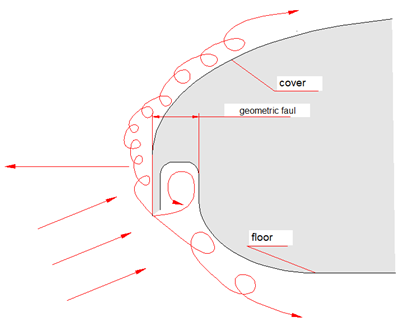

schematic airflow on its front |

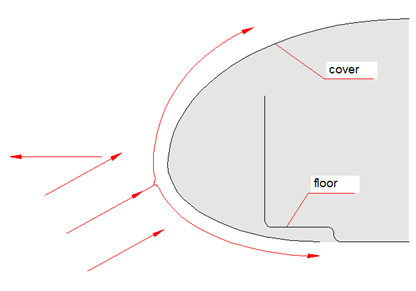

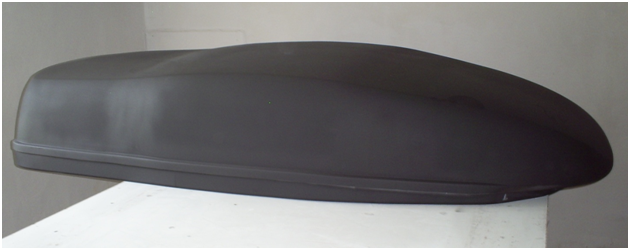

Front view of Aero-Box  |

|

schematic airflow on its front |

Comments of an aerodynamics specialist: Improved aerodynamic properties of Aero-Boxes result from the smooth profile of their front part. It is especially important if you consider the “velocity field” which the box on the vehicle roof is in. A majority of standard roof boxes has a geometric fault at the joint of the cover with the floor, up to 20 to 25 mm, which is responsible for the aerodynamic drag. The said geometric fault creates the so-called turbulator in oblique airflow. It is responsible for drag coefficient rise from Cx=0.2 (for a smooth solid) to Cx=0.35. The above values are confirmed both by calculations and by the studies carried out. It is important that standard roof boxes placed in a parallel “velocity field”, e.g. in a wind tunnel, will show Cx values close to 0.2 mentioned above when perceived as isolated objects. After the car roof has been modelled, Cx increases rapidly.

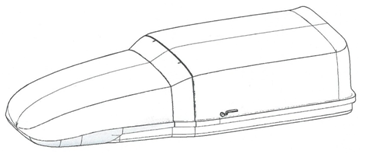

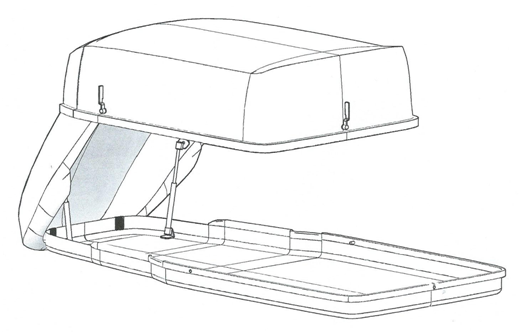

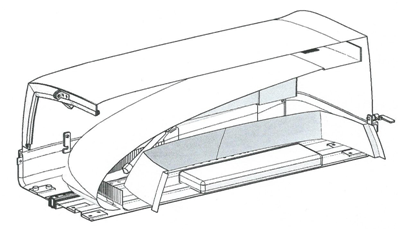

In the presented version of Aero-Box optional additional base beams were used. They enable us to carry additional cargo, especially the one with the dimensions exceeding the length of the box itself, e.g. skis or surfboard. In the commercially available surfing boxes the additional base beams are an integral part of the box. In the presented Aero-Boxes the beams are “optional” equipment. They can be installed or not. They can be present on the box permanently in the backward position and moved only when necessary. In the “backward position” both beams make a spoiler and as a combined solid create a minimum drag.

|

|

|

|

Aero-Box

550 Technical parameters: Capacity Length Width Height Mass Fixing Base beam sparing Cover raising |

- 550 dcm3 - 2020 - 1010 - 400 - 20 kg - typ „U” - 550- 800 - hydro-pneumatic |

| Performance

technology The entire box is made from polyester and glass laminate, moulded manually. |

||

Aero-Box 550 „prima” (in progress)

|

|

|

|

Information for those interested

1. Suggested

development directions:

- Development of 2

additional options with the dimensions and design different from the

demonstrated ones. It

is pointless

and ineffective

to multiply the options.

- Transfer

from the

manual moulding technology to the "vacuum" technology, i.e. light

RTM. It results in reducing weight by

about 3–4 kg,

increasing quality and

workmanship repeatability.

- Replacement of polyester-glass

laminates with "ABS" materials - necessary to increase production scale.

2. Carrying

out purposefulness analysis of the “structural and

technological leap”

It is necessary to

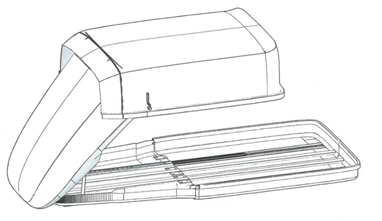

analyse a prospective market with respect to the purposefulness of

using the

advanced roof box design with a divided cover as per figure below.

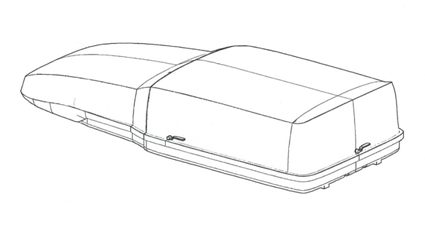

Standard version

|

|

Folded version

|

|

|

|

| Please note: The “unique”, “significant” properties are a subject of application submitted in the Polish Patent Office. | |